Customers new to shrink sleeve labeling machines or new to purchasing a set of devices for their product containers need to become more familiar with sleeve labeling machines. So we, Procus Machinery, a professional manufacturer in China, will briefly introduce what a sleeve labeling machine is, how it works, and other vital aspects to consider when purchasing one.

What is a Shrink Sleeve Labeling Machine?

Shrink sleeve labeling machine is designed to apply shrinkable sleeves to the surface of containers, such as bottles, jars, cans, or plastic cups. These shrink sleeves, typically made of heat-shrinkable films like PVC, PETG, or OPS, are placed on containers and then exposed to heat, causing them to shrink and conform to the container’s shape. This labeling technology is becoming increasingly popular in the packaging industry, as it can offer a 360-degree coverage area for product labeling and branding.

Shrink sleeve labeling machine is also called a shrink sleeve label applicator, sleeve labeling machine, or shrink sleeve labeler.

Advantages of Shrink Sleeve Labeling Machines

Shrink sleeve labeling machines offer many advantages, revolutionizing the labeling process for various industries. As a leading choice for product packaging, these machines provide exceptional benefits:

1. Versatility: Shrink sleeve labeling machines can handle various container shapes and sizes, from bottles to cans and jars. Their adaptability allows for seamless labeling on different packaging types, offering consistent and professional branding.

2. 360-Degree Decoration: Unlike traditional labels, shrink sleeves provide full-body coverage, allowing eye-catching designs to wrap around the entire container. This 360-degree decoration maximizes branding opportunities and enhances product visibility on store shelves.

3. Tamper-Evidence and Protection: Shrink sleeves provide tamper-evident seals that safeguard product integrity. Once applied, they adhere tightly to the container, making it evident if the packaging has been compromised, ensuring consumer safety and trust.

4. Durable and Resistant: Shrink sleeves resist moisture, UV light, and abrasions, ensuring the label remains intact and vibrant throughout the product’s lifecycle, even in challenging environments.

5. High Production Speeds: These machines are engineered for high-speed labeling, maximizing production rates and meeting clients’ demands efficiently.

6. Easy Using: Shrink sleeve labeling machines offer user-friendly operation and quick changeover between label sizes and product types, minimizing downtime and increasing productivity.

With these advantages, shrink-sleeve labeling machines empower businesses to elevate their packaging game, strengthen brand identity, and deliver an unforgettable consumer experience, ultimately contributing to business growth and success.

Applications of Shrink Sleeve Labeling Machines

Shrink sleeve labeling machines find applications in various industries, including food and beverage, pharmaceuticals, cosmetics, personal care, and household products. Their ability to accommodate diverse packaging requirements and visually appealing results make them popular across various sectors.

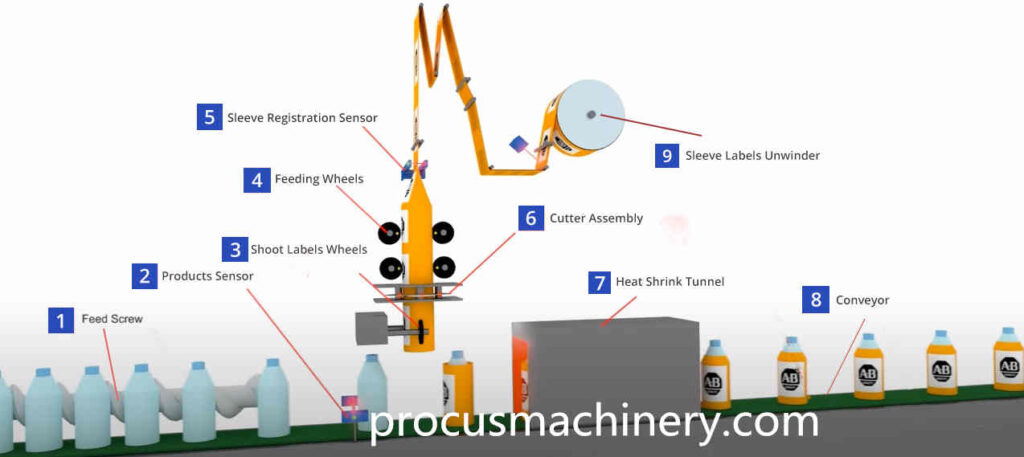

How Does Shrink Sleeve Labeling Machine Work?

Shrink sleeve labeling machines have various configurations, including automatic, semi-automatic, and fully integrated systems. They can handle different container shapes, sizes, and materials, making them versatile solutions for various industries.

But the primary working process is applying the shrink sleeves onto the containers, and then the labeled containers move through the shrink tunnel, where heat causes the shrink sleeves to shrink and tightly conform to the containers.

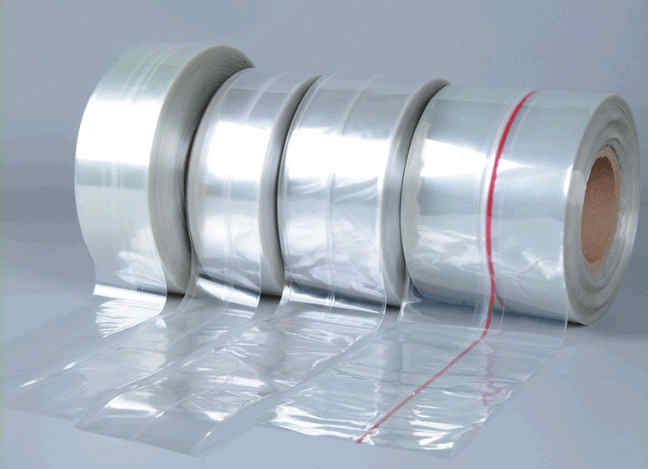

Shrink Sleeve Labels

Shrink sleeve labels are a popular choice for product packaging and branding; these shrink labels are made of heat-sensitive polymer films that have the unique property of shrinking when exposed to heat. The labels are designed to fit tightly and conform to the shape of the container, providing a seamless, 360-degree decoration.

Shrink sleeve labeling machines are compatible with various heat-shrinkable label materials. Standard options include PVC, PETG, OPS, and PLA films.

The shrinking percentage of shrink sleeves refers to the amount the sleeve will shrink when exposed to heat during the labeling process. This shrinkage is crucial as it allows the sleeve to conform to the shape of the container tightly, providing a secure and seamless labeling solution. Typical shrink percentages for different materials are as follows:

PVC (Polyvinyl Chloride): PVC shrink sleeves have a high shrink percentage, usually 40% to 75%. This high shrinkage capability allows them to fit tightly around containers of various shapes and sizes.

PETG (Polyethylene Terephthalate Glycol): PETG shrink sleeves have a shrinking percentage in the range of 50% to 78%. Like PVC, PETG offers excellent shrinkage, making it suitable for products with complex and irregular shapes.

OPS (Oriented Polystyrene): OPS shrink sleeves typically have a shrinking percentage of around 50% to 65%. They are known for their excellent clarity and gloss, making them ideal for products requiring a premium appearance.

PLA (Polylactic Acid): PLA shrink sleeves have a shrinking percentage of approximately 45% to 70%. PLA is an eco-friendly and biodegradable material, making it a preferred choice for environmentally-conscious brands.

The appropriate shrink percentage is crucial based on the product’s specific requirements and the container shape. A higher shrink percentage may be needed for irregularly shaped containers to achieve a perfect fit, while products with more average conditions can use shrink sleeves with lower shrink percentages. Proper consideration of the shrink percentage ensures that the sleeves provide a secure and visually appealing product labeling solution.

The Significance of the Shrink Tunnel

Shrink tunnel plays a crucial role in shrink sleeve labeling, as it activates and evenly distributes heat to the containers’ labels. This process is essential to achieve a tight and seamless fit, enhancing the appearance and security of the packaged product. Customers can understand the significance of the shrink tunnel through the following key points:

1. Heat Activation: The shrink tunnel applies controlled heat to the shrink sleeve labels made of heat-sensitive polymer films. This heat activates the memory properties of the film, causing it to shrink and tightly conform to the shape of the container. The result is a smooth and precise label application, even on irregular-shaped containers.

2. Tamper-Evidence and Product Protection: Shrink sleeves offer tamper-evident properties, and the shrink tunnel is instrumental in ensuring this feature’s effectiveness. Once the heat-shrink process is complete, the sleeve forms a tight seal around the container, indicating if the package has been tampered with or opened.

3. 360-Degree Labeling: Shrink sleeves enable 360-degree labeling, allowing businesses to utilize the entire surface area of the container for branding and information. The shrink tunnel ensures that the label adheres evenly around the container, presenting a visually appealing and professional appearance from every angle.

4. Versatility: Shrink tunnels can be used with various shrink sleeve labels and container materials, including plastic, glass, and metal. They can handle different container shapes and sizes, providing a flexible solution for diverse packaging needs.

5. Efficiency and Speed: Modern shrink tunnels are designed for high-speed production lines, allowing for efficient and rapid label application. They contribute to increased production throughput and streamline the packaging process.

6. Quality and Consistency: The shrink tunnel’s precise temperature control ensures consistent heat distribution, resulting in uniform and well-fitted shrink sleeve labels on each container. This level of quality control enhances the overall packaging aesthetics and brand presentation.

Shrink tunnel is an integral part of the shrink sleeve labeling process, ensuring the effective activation of heat-sensitive shrink sleeve labels and delivering superior packaging results. Its significance lies in achieving a secure and visually appealing packaging solution, offering brand visibility, tamper evidence, and product protection. It is an essential component in modern packaging operations across various industries.

Conclusion:

Shrink sleeve labeling machines provide a versatile and efficient solution for enhancing product packaging and branding. By understanding these machines’ fundamentals, advantages, applications, working mechanisms, and compatible sleeve labels, you can make well-informed decisions for your packaging needs. Whether you are in the food and beverage industry, pharmaceuticals, or other sectors, utilizing shrink sleeve labeling machines can elevate your product’s visual appeal and security. Embrace the benefits of shrink sleeve labeling machines to optimize your product’s packaging.