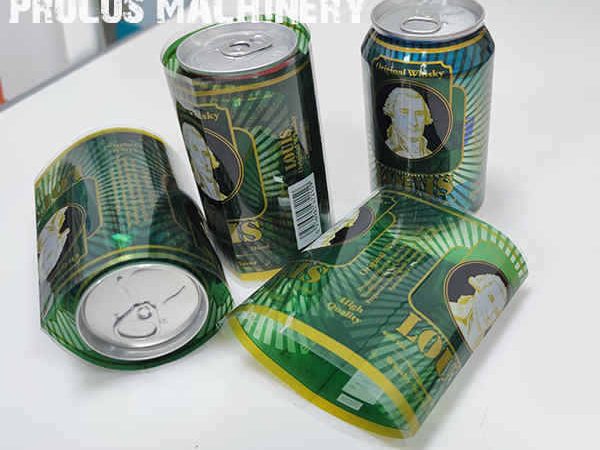

Shrink Sleeve Labeling Machine for Craft Beer Cans & Aluminum Cans

Aluminum cans are becoming an increasingly cost-effective choice for various brands due to their sustainability and high recycling rate, as well as their lightweight, stackable, and sturdy nature. This can save companies both time and money in product packaging. As a result, creating a unique design for their aluminum cans has become an important task for these brands.

PROCUS MACHINERY specializes in manufacturing sleeve labeling machines that provide different sleeve labeling solutions for beer and aluminum cans. Procus Machinry can offer both shrink sleeve labeling machines and sticker labeling machines for beer and aluminum cans. These machines are gaining popularity because they can meet the small quantity customization requirements.

Solution 1: Shrink Sleeve Labeler for Filled Craft Beer Cans & Aluminum Cans:

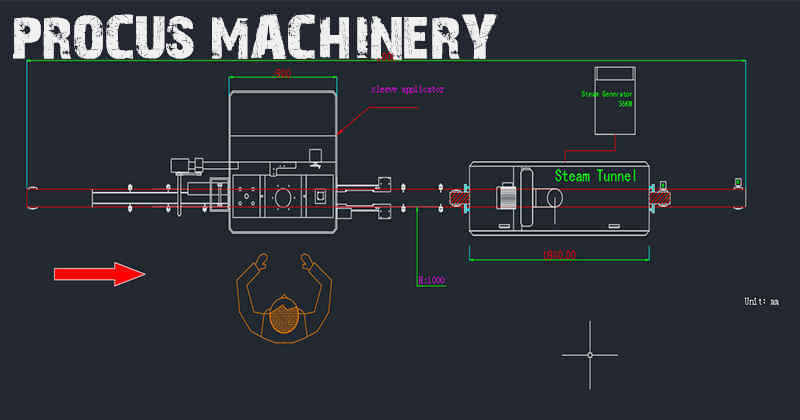

For filled beer cans or aluminum cans, We often recommend a fully automatic sleeve applicator with steam shrink tunnel to apply and shrink the sleeve labels on the cans. Because automatic shrink sleeve labeling machine with steam shrink tunnel can provide high speed production and perfect sleeve label shrinking.

Steam shrink tunnel need to work with steam boiler, If you don’t have the steam boiler in workshop, then the steam generator could be instead of it.

Sometimes the air knives machine is also required to work with steam shrink tunnel. because with steam tunnels, the product will have a small amount of moisture vapor or droplets on it upon exiting the tunnel. The air knives could help to dry them.

Solution 2: For Empty Craft Beer Cans & Aluminum Cans:

For empty craft beer cans & aluminum cans, most of our customers have chosen the electric heat shrink tunnel instead of steam shrink tunnel for shrinking the sleeve label onto empty beer cans.

Because when the empty beer cans go through the steam shrink tunnel, there will be a small amount of moisture vapor or droplets inside and on surface of the empty cans upon exiting the tunnel. This is easy to breed bacteria and mildew inside cans. Especially, some beer & aluminum cans manufacturers need to store or deliver the finished shrink sleeve cans for their customers, this may need a few more days, it is more easy to breed bacteria inside the beer cans.

Reason 2: Using electric heat tunnel, the high temperature inside the electric heat tunnel can help disinfect some bacteria inside cans to meet food-grade production requirements.

Option 1: Fully automatic shrink sleeving applicator with steam shrink tunnel for the filled beer & aluminum cans

Layout drawing of the filled craft beer cans & aluminum cans sleeve labeling machine

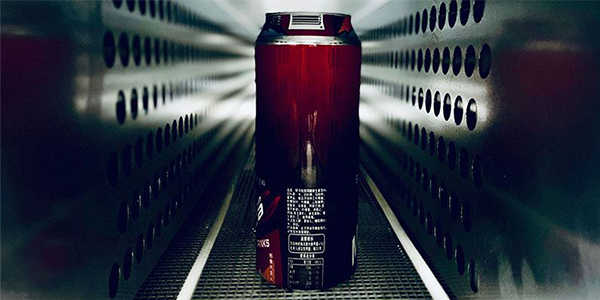

Steam Heat Shrink Tunnel

Steam shrink tunnels are the most effective types of tunnels for the shrinking of partial-body & full-body shrink labels. Steam heat shrink tunnels also can provide high quality shrink results on complex containers, such as oval, hourglass, tapered and offset neck shapes. For the filled beer & aluminum cans, steam shrink tunnel is the best choice.

But It still has some Challenges When Using Steam.You need have a good stable supply of steam at a moderate pressure. So This requires the in-plant steam boilor, which also often is used for other purposes. Or It required the installation of a steam generator to supply the stable steam, typically 24 to 48 KW in power, Maybe higher power, this depends on your own products.

In addition to this, when using a steam shrink tunnel, a set of air knives maybe are needed too. Because the beer & aluminum cans or other containers will have a small amount of moisture vapor or droplets on it upon exiting the steam tunnel. Then in this case, customers will add the air knives to dry the beer cans or other containers once they exit the steam tunnel.

Ask For A Price List About Filled Cans Sleeve Machine

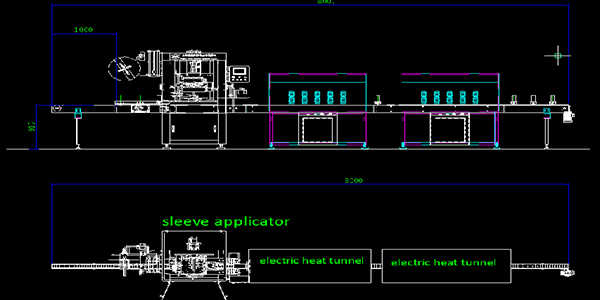

Option 2: For The Empty Craft Beer Cans & Aluminum Cans:

Electric Heat Shrink Tunnel is Suitable for Kinds of Empty Craft Beer Cans & Aluminum Cans

Electric Heat Shrink Tunnels

Electric heat shrink tunnel is also called convection hot air shrink tunnel. Its heater elements provide a highly efficient, reliable and low cost means of rapidly supplying heat directly to air, which is delivered to the heat shrinkable sleeve labels on containers.

To achieve the optimal shrinking sleeve labels for producing a great looking product, According to the characteristics of specific products and the requirements for production speed, two or more electric heat tunnels of the same or of different types might be used in sequence.

Layout Drawing of The Empty Craft Beer Cans & Aluminum Cans Shrink Sleeve Machine

Get A Price List Of The Empty Craft Beer Cans Shrink Sleeving Machine

Solution 3: Craft Beer Cans & Aluminum Cans Sticker Labeling Machine.

Fully automatic sticker labeling machine can be used for both filled beer & aluminum cans and empty beer & aluminum cans. It is totally different from the shrink sleeve machine.

The sticker labeling machine is working like below video.

Filled Craft Beer Cans Sticker Labeling Machine

Empty Craft Beer Cans Sticker Labeling Machine

What is the difference between beer cans sleeving machine and beer cans sticker labeling machine?

For craft beer cans & aluminum cans, shrink sleeving machine and sticker labeling machine both have advantages and disadvantages.

Shrink sleeve labeling machine can shrink the heat shrinkage sleeve labels on the cans in 360 degrees with a full body great looking, and then make your product stand out on the shelf. And Beer cans sleeve labeling machine has fast production speed and high output. Production time is saved, which in turn reduces company costs.

Sticker labeling machine for beer cans has a small footprint. and the cost of beer cans sticker labeling machine is cheaper than shrink sleeving machine.

Conclusion

No matter the specifics needed for your product, PROCUS MACHINERY will customize the ideal shrink sleeve label machine with shrink tunnel system for your application. We are at your service and ready to test your products in our factory to help determine the correct material specifications for the successful launch of your new package.

Ask For A Quote About Beer Cans Solutions

We will get back to you as soon as possible