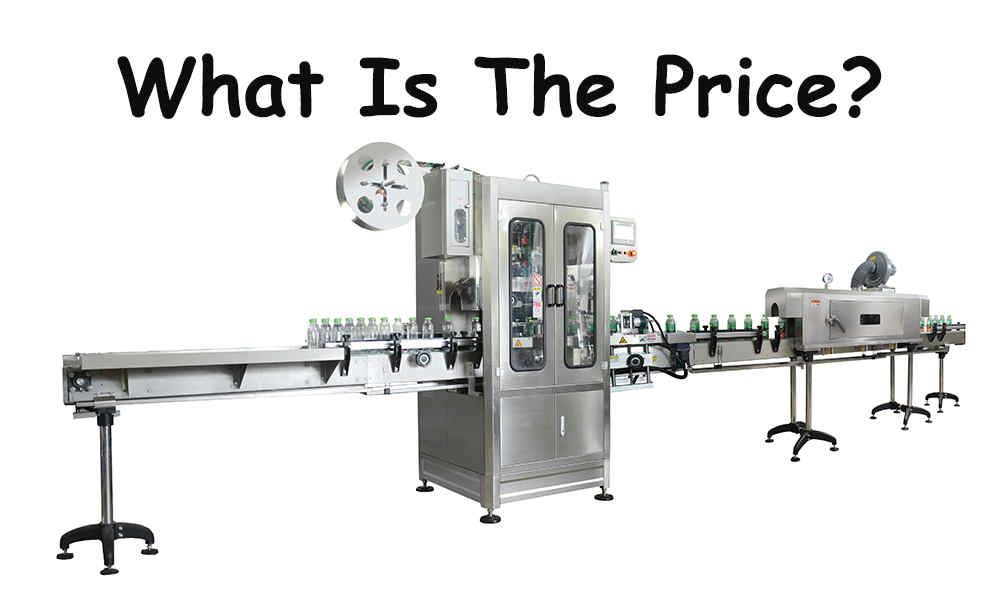

If you are exploring the product packaging, you may come across a critical machine – the shrink sleeve labeler – that grabs your attention. However, when it comes to understanding the pricing of these machines, things can get confusing. Let us take a deeper look into the cost of these machines.

Pricing of Fully Automatic Shrink Sleeve Labelers

A basic fully automatic sleeving machine can cost anywhere from $7,000 to $20,000. Unlike typical consumer goods, fully automatic sleeving machines don’t have a standard price tag. They are custom-built based on product characteristics and specific client requirements. Since the market is full of options differing in quality and service, leading to a wide price range. Choosing a manufacturer known for quality and reliable service is critical when investing in one.

However, most manufacturers could offer a free quote given the product specifics and requirements, and They will provide a detailed estimate. While some might provide a quote in a few hours, others might take days. It’s all about their internal processes and the attitude of sales.

Pricing of Semi-Automatic Shrink Sleeve Labelers

Semi-automatic sleeving machines, commonly referred to as shrink tunnels, have a relatively defined price range. Electric shrink tunnels typically cost between $500 and $1,000, while steam tunnels range from $3,000 to $6,000.

Factors Influencing Pricing

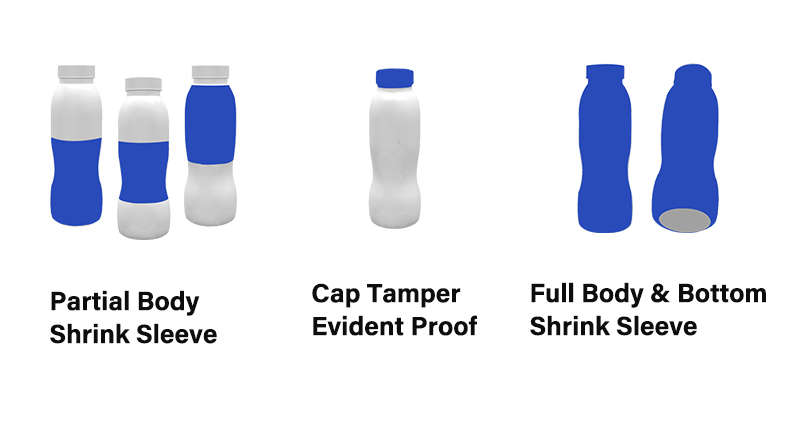

– Shrink Sleeve Placement on the Bottle: The sleeve positions include partial body shrink sleeves, whole body shrink sleeves from the bottle cap to the bottom, wrapped around the bottle base, and bottle cap tamper evident proof shrink sleeves. These different labeling positions determine the design and selection of the sleeving machines. Furthermore, we sometimes need to add various accessories and equipment for shrinking labels at other positions, so the price of the shrink sleeve labeler naturally varies significantly.

– Empty Bottles vs. Filled Bottles Labeling: Empty and filled bottles require different solutions for optimal shrinking. Empty bottles are normally recommended with electric shrink tunnels, but to achieve the best results, multiple electric tunnels might be necessary, sometimes up to three or four. On the other hand, steam tunnels are usually guided for filled bottles due to their superior shrinking capabilities. One or two steam tunnels can often match the efficiency of multiple electric tunnels.

– Production Speed: Differences in production speed lead to recommendations for different corresponding shrink sleeve labelers. Moreover, the pace of production influences the number of shrink tunnels needed; a faster production rate necessitates more shrink tunnels. Thus, the price of the shrink sleeve labeler is significantly related to the speed of production.

– Bottle Material: Different materials might require different labeling solutions, components, or shrinking methods. All these contribute to the overall pricing.

Conclusion

Understanding the cost of a shrink sleeve labeler goes beyond merely looking at the price tag. It requires a deeper dive into your product requirements, desired speed, and even the material of your bottles. It’s a mixture of customization and functionality. Remember, it’s not just about the machine; it’s about finding the right fit for your production needs. Invest wisely!